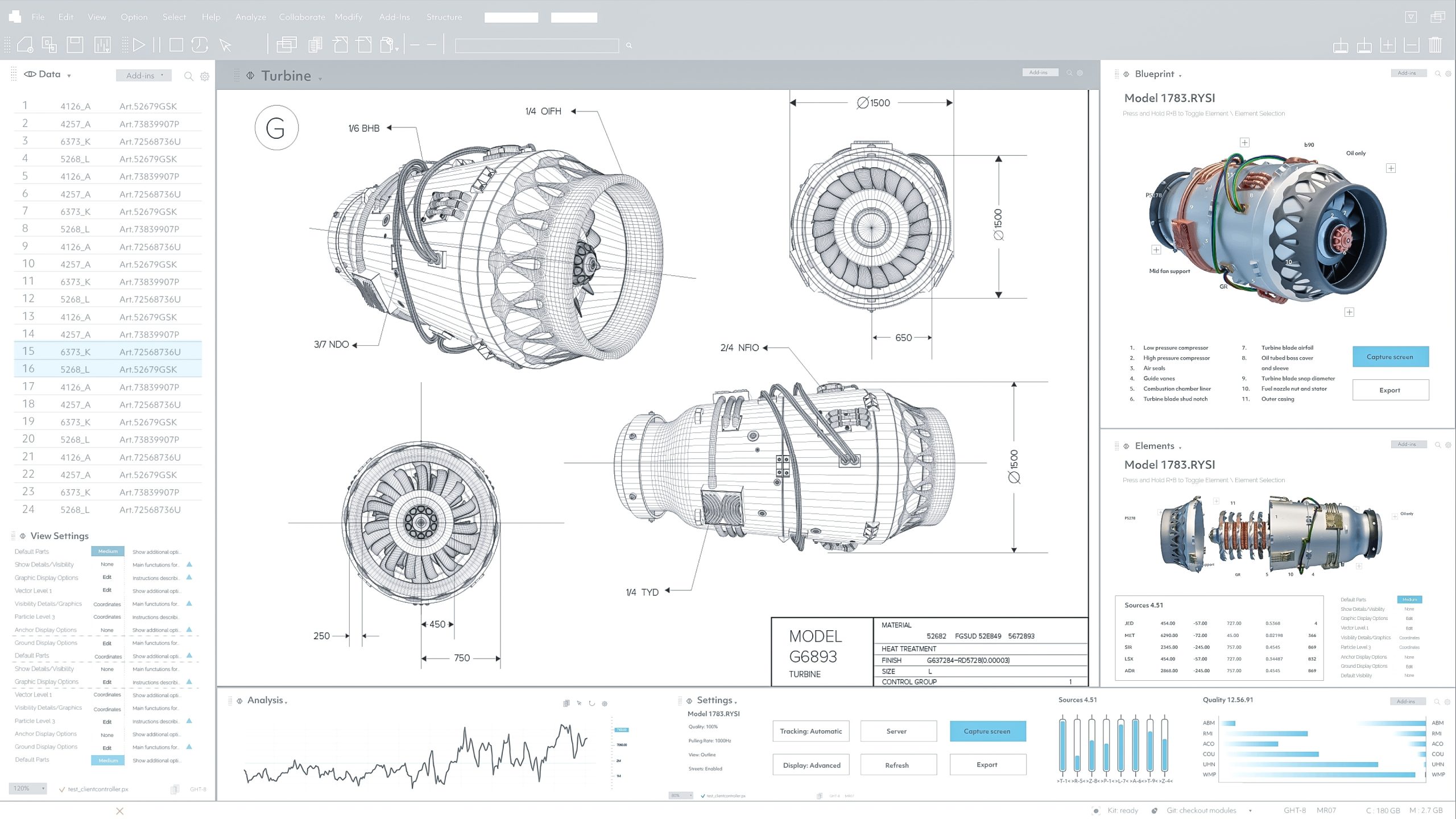

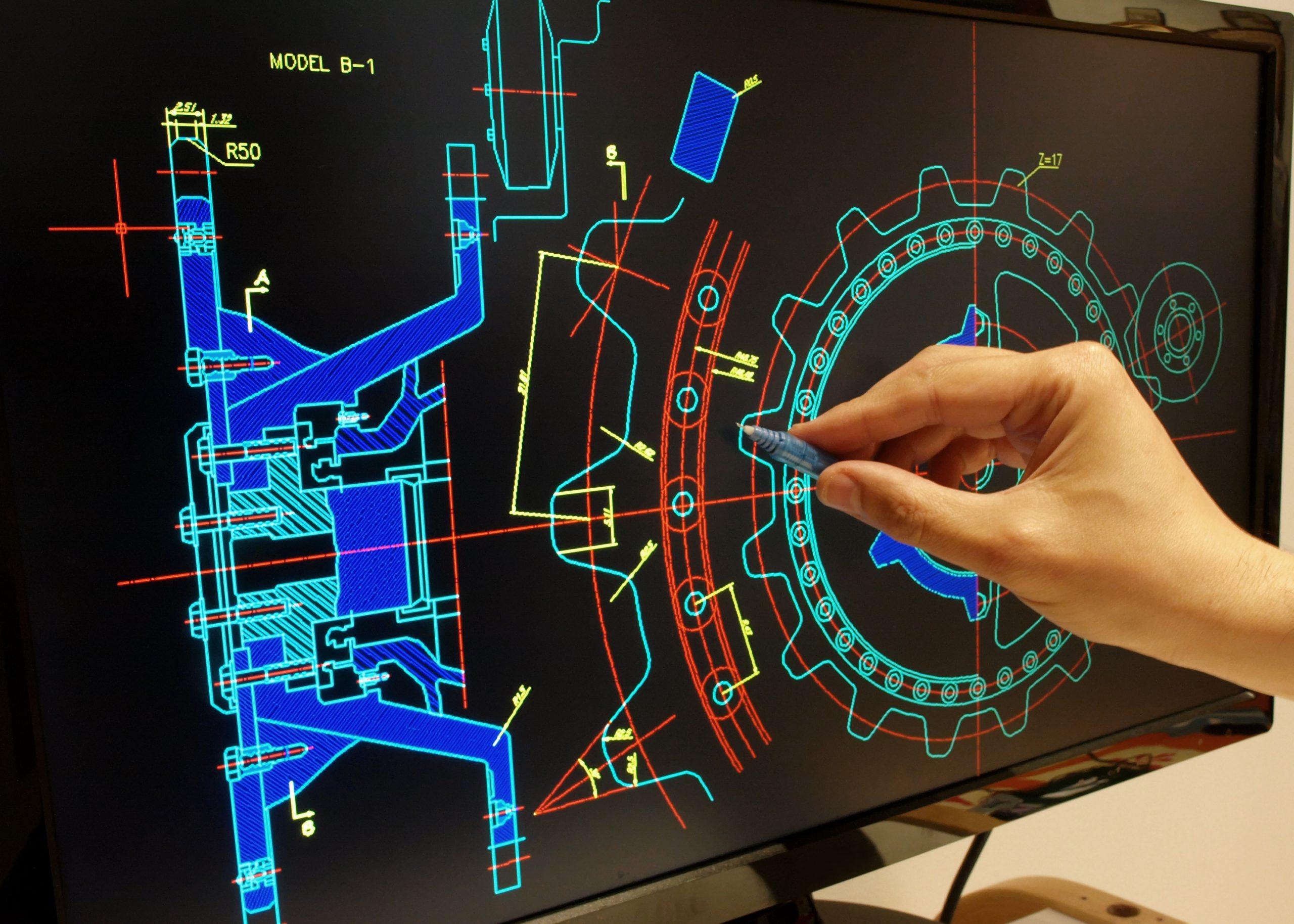

3D Design

The fundamentall base of all hardware products is CAD design, it facilitates all stages of development from Concept Feasibility through to Production Release and Mid-Lifecycle Upgrades. From the very start the design should be developed in line with your company's targets for timing, cost, manufacturing volume, usability and an extensive list of key requirements.

We use the industry-leading Siemens NX CAD software to create the designs that you require, with constant feedback and progress updates along the way to allow you to see the product coming into fruition.

PEC can take a varied level of ownership, depending on the customer's preference. We're able to complete small CAD tasks for product updates, through to complete ownership of taking your idea through to a ready-to-sell product. Please discuss your requirements with us so we can tailor the service to match your requirements.

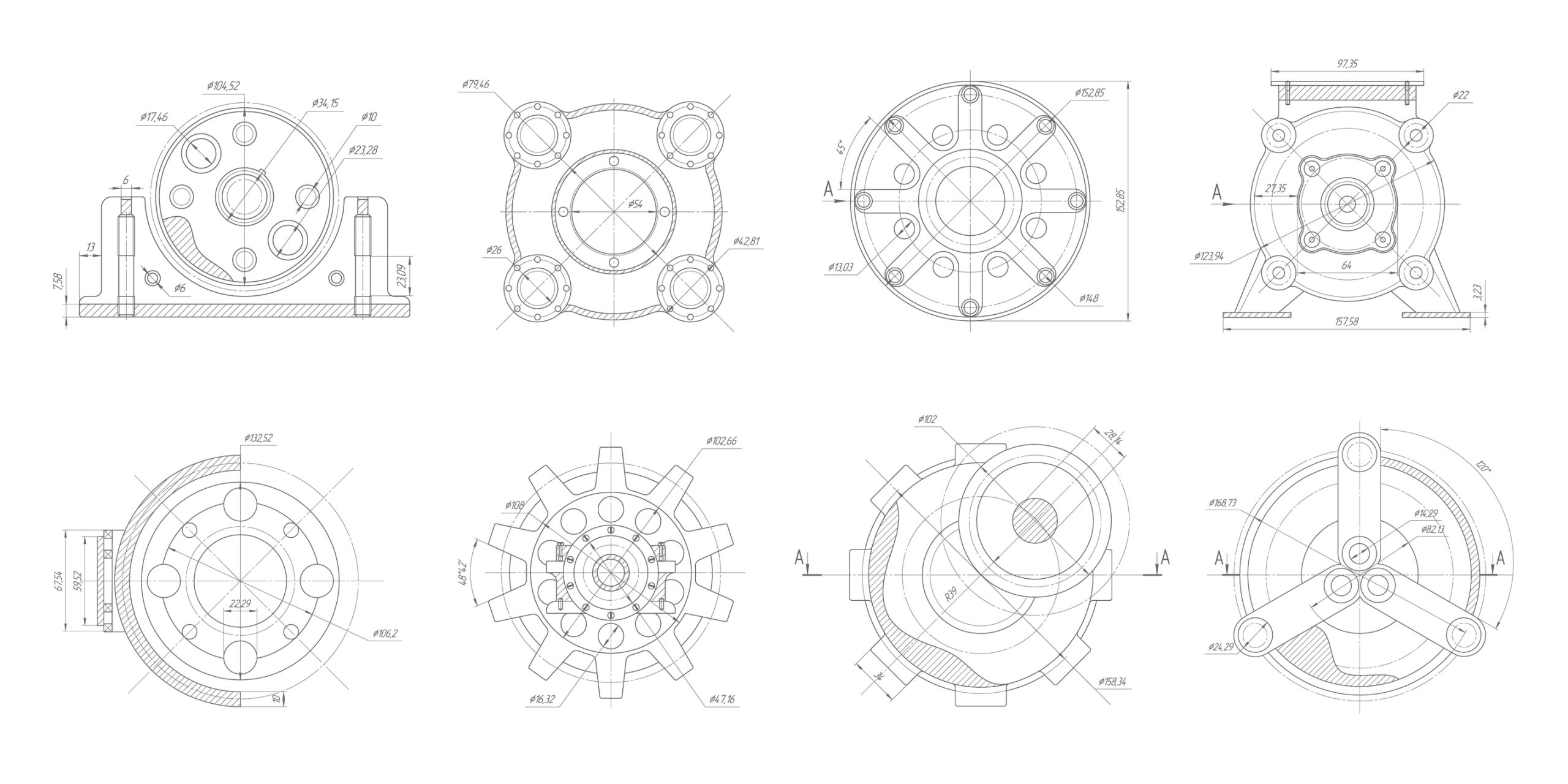

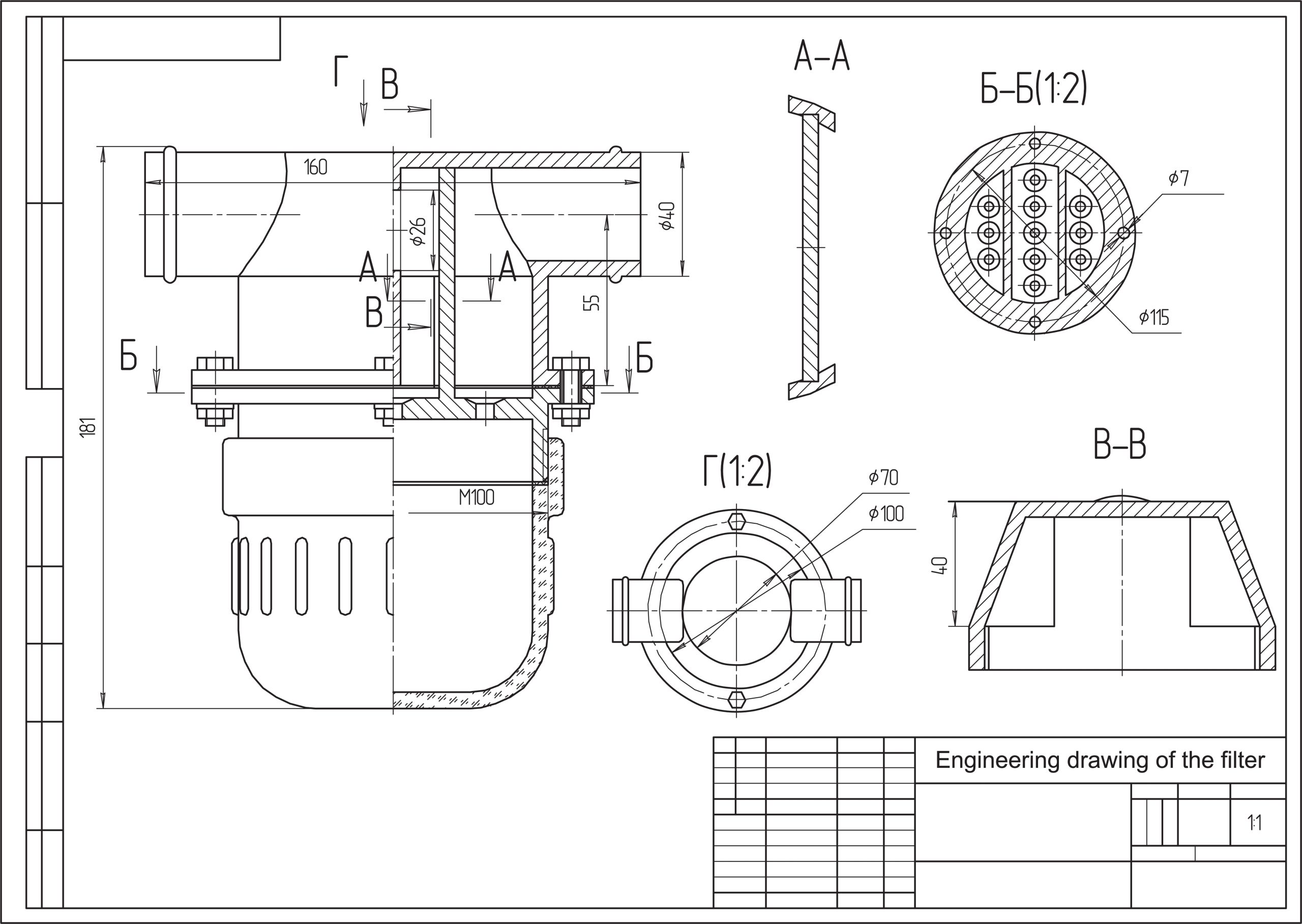

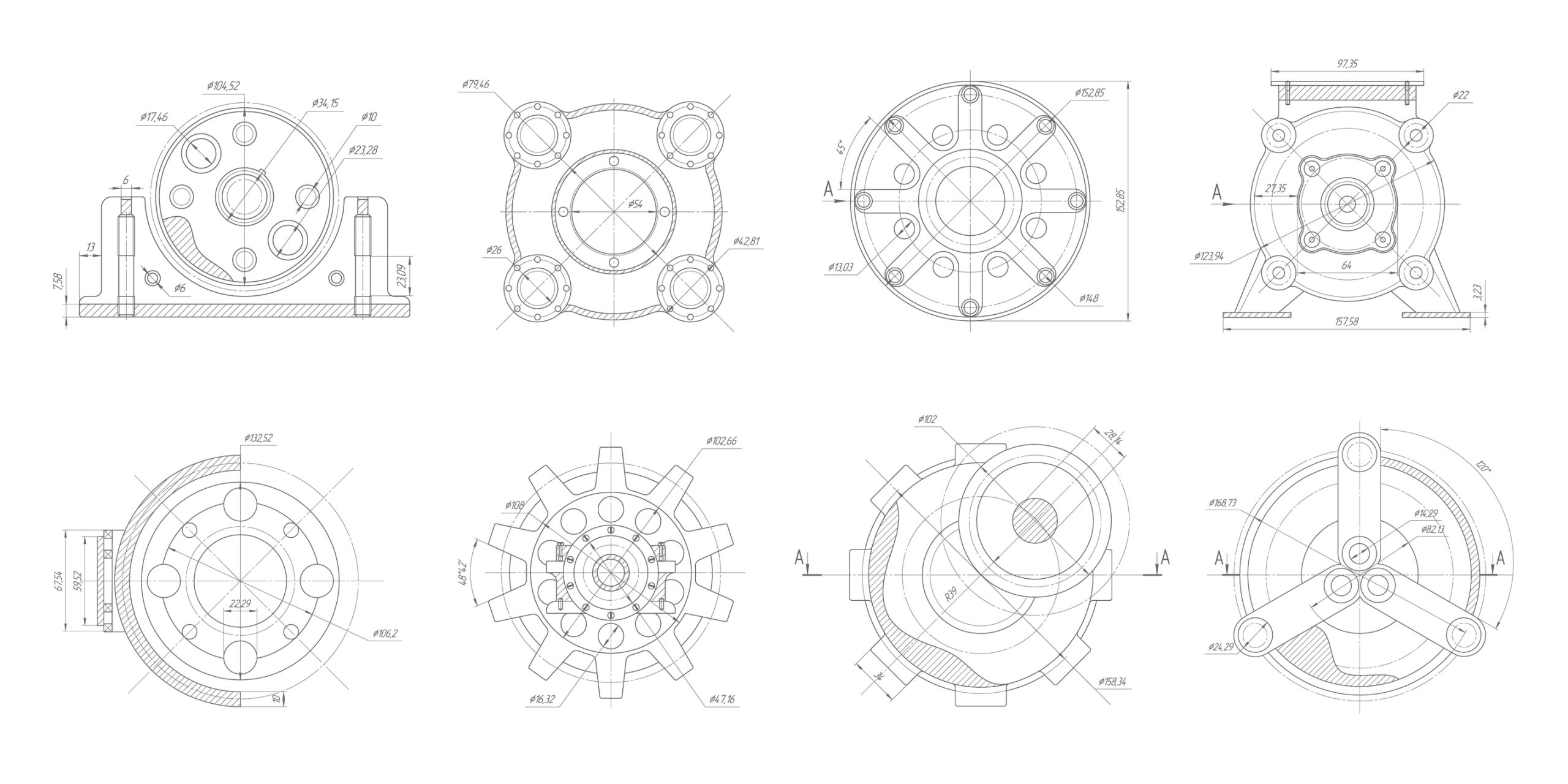

2D Drafting & PMI

If you have existing 3D models, or ready-made designs that require manufacturing drawings, customer drawings, updates or optimisation, we can apply industry-standard GD&T (geometric dimensioning and tolerancing) to 2D drawings and 3D PMI assemblies. As well as ensureing manufacturability, we will review tolerance stackups and apply feasible interface tolerances for a reliable always-fit assembly.

GD&T is completed to either BS8888 or ASME Y14.5 standard, ensuring that manufacturing and quality control will delivery the performance and reliability you require.

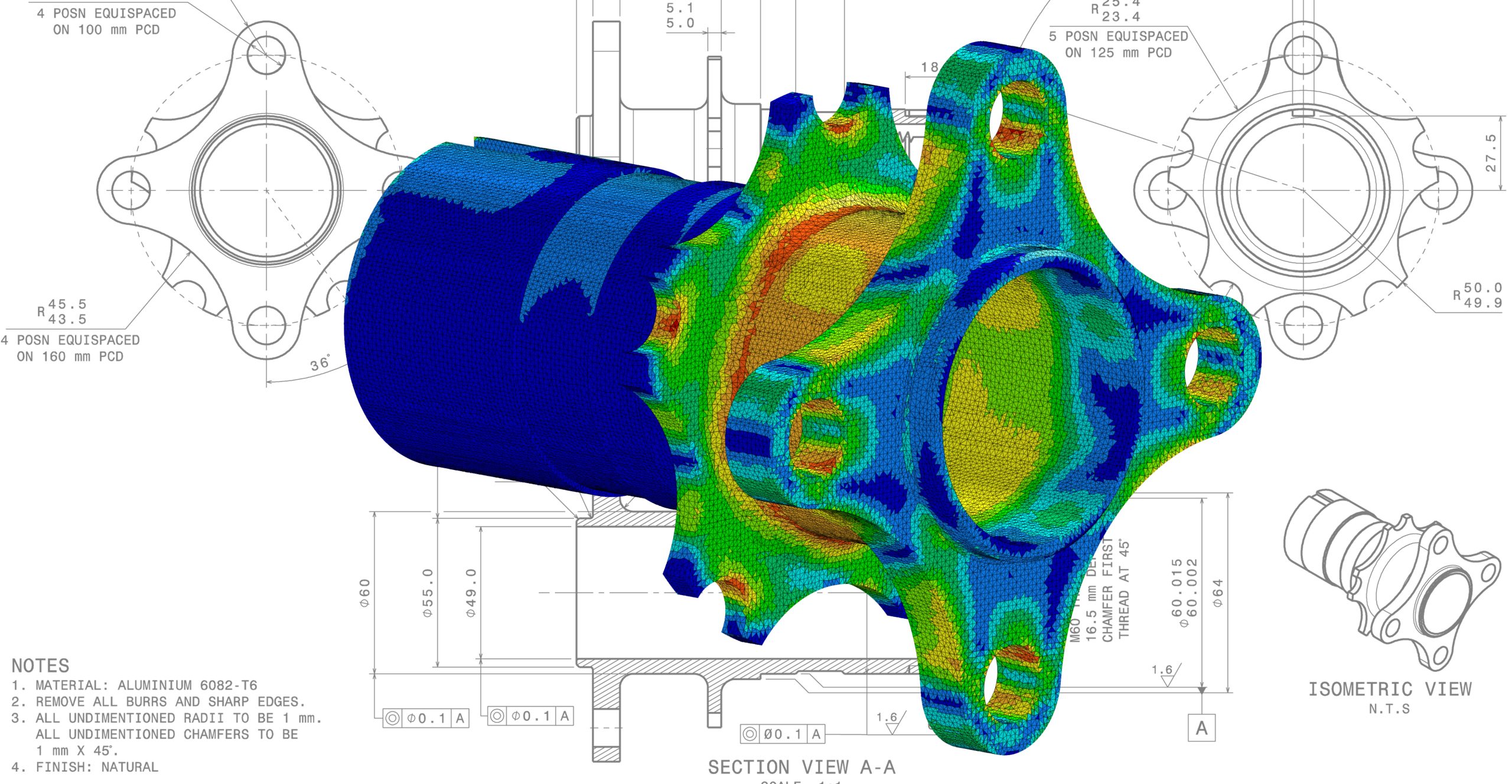

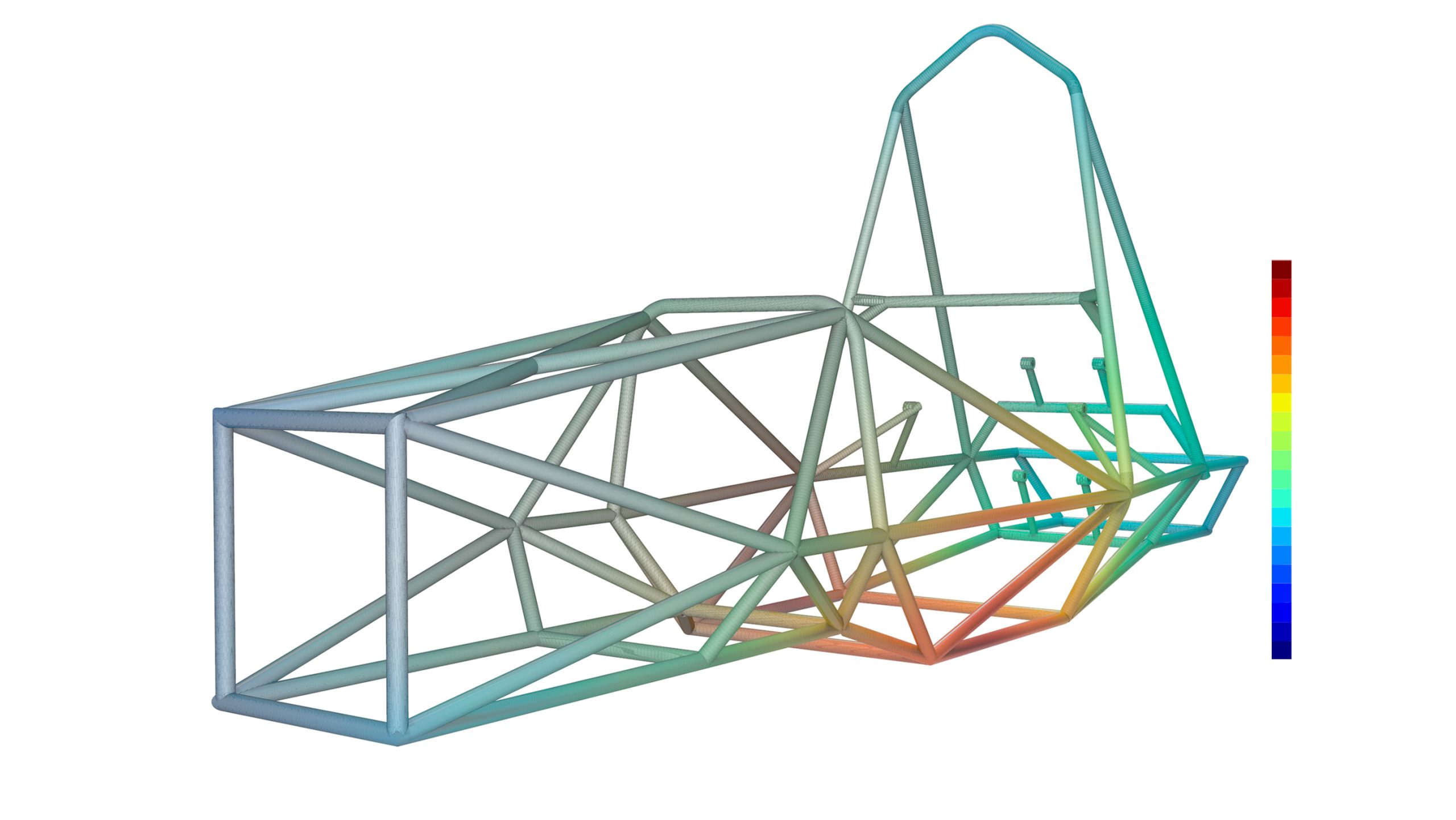

FEA

Computerised simulation is an extremely cost-effective way to predict material failure and iteratively improve designs for robustness and longevity. This can be used in parralel to physical testing, or as an alternative method with reduced cost and timing impact.

We use advanced Finite Element Analysis software to detail material stresses and deflections in real-world applications. As such we can provide confidence in your product's performance during customer usage.

A-Surface Design

Almost all consumer products have a visual A-surface that requires optimised continuity to ensure high perceived-quality and a positive user experience. Using NX advances surface modelling we can optimise existing designs, as well as creating completely new surface designs, for a customer-centric and visually pleasing finish.